By: Michelle Pawelski

Photos: Bailey Sadowsky

Issue: November 2025

Last September, after a decade of honing his skills with manufacturers across the Black Hills, Brock Smith took a leap of faith. The South Dakota Mines graduate and Wyoming native launched his own venture, Divergent Designs, giving himself one year to see if his dream of running a design and engineering company could take shape.

Little did he know where that leap would take him.

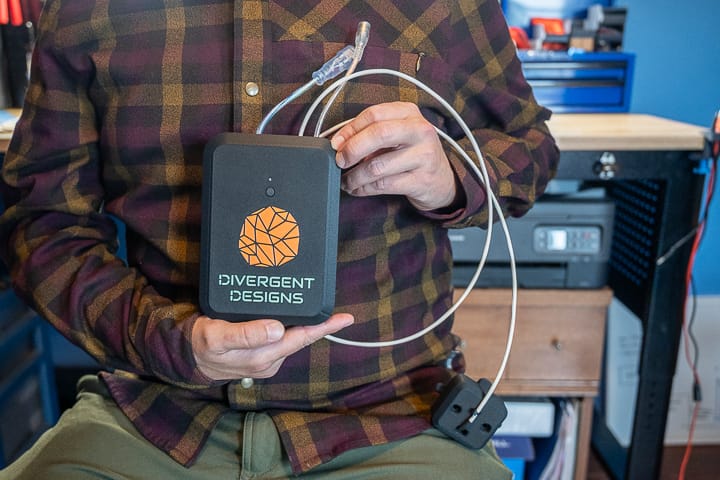

In that year, Brock made his mark on the region’s growing manufacturing scene by building a company that combines manufacturing with technology to solve problems and create beautifully engineered products. From cutting-edge research equipment bound for Switzerland to a radar-based Smart Sign Controller recently voted the “Coolest Thing Made in the Black Hills,” Brock is proving that his dream of entrepreneurship has become a reality.

“I gained a lot of experience while I was working at all these smaller manufacturers,” Brock said. “A few of them manufactured on site, so I gained a lot from that and then learned how to work with the factories. Those experiences gave me a real understanding of what it takes to run a business.”

The idea for Divergent Designs originated a few years earlier when Brock started taking on side projects as a hobby. An avid mountain biker, he began experimenting with 3D printing stainless steel bike frames. His hobby began to open doors when a university in Switzerland reached out, seeking his expertise in designing a specialized product.

“That was really the catalyst for me to start Divergent Designs, and that is what I have been working on for most of last year and the beginning of this year,” Brock said. “We exported some equipment to Switzerland, and they’ve been testing it, and it has been going well.”

Brock’s process follows a hands-on approach, designing, building a prototype, sending it to clients for testing and refining to best meet their needs.

He was working on his Switzerland product when Black Hills Federal Credit Union (BHFCU) reached out with an idea. With more institutions utilizing Interactive Teller Machines (ITMs), advanced ATMs that connect customers to live remote tellers, BHFCU sought a solution that maintained customer privacy while incorporating modern aesthetics.

Working with BHFCU, Brock developed the Smart Sign Controller, which uses a discreet radar sensor that signals when the kiosk is in use without exposing the customer’s activity. While the concept is nothing new, the execution is unique, said Brock, who had already been experimenting with the motion-activated technology on one of his own products when BHFCU contacted him.

Brock built four Smart Sign Controller prototypes placed in the BHFCU’s downtown branch and tested over the summer.

“We added a few things to the software and modified the sensitivity to get them working how they wanted. It is a fun partnership to be involved in,” he said.

“They were getting positive feedback from members and employees, so they decided to purchase more for all their branches.”

Brock also volunteers with a local bike club, helping to maintain the city’s trail system. He began developing a trail traffic counter to track usage across different paths, providing data on which trails are most popular and helping the club prioritize maintenance. The information could also serve as evidence when applying for grants to fund new trail projects.

“It was a side passion project, but that is where I was introduced to the technology for the radar sensors,” Brock said. “I was testing the equipment for the traffic counter, and it worked well for the bank project as well.”

Brock operates Divergent Design from his home, where his shop is fully equipped with all the necessary manufacturing tools, including welders, 3D printers, and a range of precision machines. Although he’s currently the company’s sole employee, Brock collaborates closely with a team of consultants, many of whom are former Mines classmates, and his wife, Laura, often lends a hand with assembly work.

“It’s certainly had its ups and downs,” Brock said of branching out on his own. “But I feel like I got some momentum, and it’s been more than I can imagine as far as the number of projects and clients coming to me to help them solve problems.”